- Electromechanical validation

- Component test

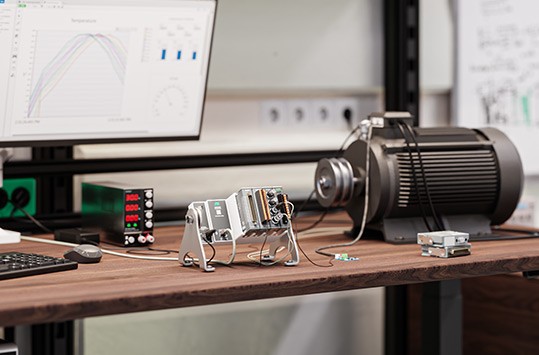

- Motor/pump test

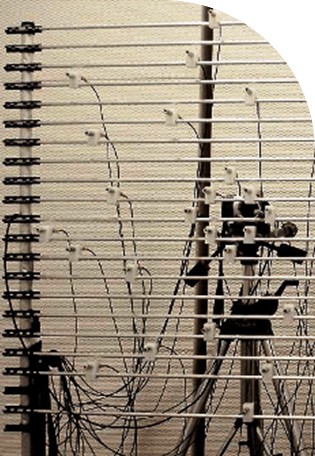

- Structural and durability test

- Noise, vibration, and harshness test (NVH)

- Research measurements

- Cycle test systems

- Performance benchmarks

- Power and thermal tests

- Power and battery characterization

- HALT/HASS measurements

- Sensor measurements