What Is Condition Monitoring?

Overview

Condition monitoring uses sensors and analysis to track the performance of components, equipment, and processes to identify parts that may need repair or replacement as part of a predictive maintenance strategy. Many performance characteristics can be measured and analyzed, with system architectures tailored to the needs of industries that include automotive, aerospace, oil and gas, and electronics manufacturing.

Contents

- How Condition Monitoring Works

- Types of Condition Monitoring

- Benefits of Condition Monitoring

- NI Condition Monitoring Hardware and Software

How Condition Monitoring Works

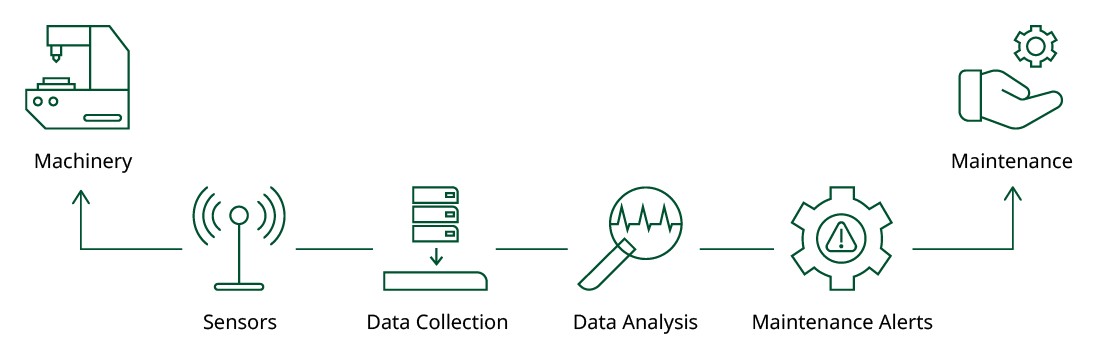

Condition monitoring uses sensors, data acquisition devices, and specialized software to enable predictive maintenance. Machines produce many data points during normal operation. Sensors collect vibration, thermal, acoustic, and other data which is sent to a DAQ device and control system for analysis. Software flags potentially troubling results for human review or can trigger an automated response to protect equipment and workers. Condition monitoring is used in industrial settings, in the field, and in test and measurement laboratories.

Figure 1: Condition monitoring process

Types of Condition Monitoring

A single piece of equipment can be subject to several kinds of condition monitoring:

Vibration Monitoring

Vibration is a common characteristic of heavy machinery and isn’t always a cause for concern. But an unusual vibration signature can be a sign that a component is worn out, unbalanced, broken, or otherwise in need of attention. Vibration monitoring usually relies on accelerometers, proximity probes, and velocity sensors to take measurements that are sent to a control system for analysis.

Learn more about vibration monitoring

Thermal Monitoring

Machine components each operate within a range of expected temperatures. If sensors detect an abnormally low or high temperature it may mean that something is wrong with the equipment or processes. Thermal monitoring sensors include thermocouples, resistance temperature detectors (RTDs), and thermistors that send data to a computer for analysis.

Learn more about thermal monitoring

Acoustic Monitoring

Learn more about acoustic monitoring

Other common types of condition monitoring include oil analysis, electrical monitoring, and pressure monitoring. Condition monitoring can be continuous (online) or intermittent (offline) regardless of what’s being measured.

Benefits of Condition Monitoring

The goal of condition monitoring is to detect issues with equipment before they cause damage or downtime. Insights gathered by sensors and analysis software power predictive maintenance, and can improve machine reliability and lifespan, reduce the costs that come with unscheduled repairs, and even minimize the chance of workplace accidents.

Condition monitoring is applied to many types of equipment and processes:

- Rotating shafts

- Motors

- Gas turbines

- Pipelines

- Reciprocating compressors

- Pumps

- Bearings

- Fans

- Engines

- Gearboxes

- Generators

- Transformers

- Circuit breakers

- Electronic components and cabinets

- HVAC systems

- Furnaces and ovens

- Server rooms and data centers

- Hydraulic system fluids

- Lubrication system oils

- Material curing processes

NI Condition Monitoring Hardware and Software

NI technology supports condition monitoring with data acquisition devices and analysis software. Our DAQ modules connect sensors to control systems and include solutions for sound and vibration and temperature measurement. NI software like LabVIEW and SystemLink™ software is used for condition monitoring and analysis, helping visualize sensor data. NI hardware and software support predictive maintenance strategies across industries, helping improve efficiency and reduce costs through smart data use.